Positioning with frequency inverters

Precise positioning – Positioning with frequency inverters

Lenze is one of the most innovative companies in Germany and employs approximately 3,000 staff throughout the world. Around 300 of these are employed in research and development, working on products, solutions, systems and services for mechanical and electronic drives as well as complete automation systems.

Since we are world-wide specialists in drive and automation technology, we understand our customers’ needs in solving their problems. We use our know-how to develop the best total solution jointly with our customers. Everything is done to identify and exploit the customer’s existing potential for value creation.

During the financial year 2008/2009 (1st May to 30th April), the turnover at Lenze was €505 million. The company’s head office is at Hamelin in Germany where the company was founded by Hans Lenze in 1947. Our largest sites are located at Extertal (Germany), Asten (Austria), Shanghai (China) and Uxbridge (USA). By locating our own companies and sales and service partners in more than 60 countries, we are right there – where our customers need us!

Lenze is a public limited company under European law (SE = Societas Europaea). At the same time, the company structure is such that it operates in the spirit of a family business. The mutual esteem among the staff is tangible, as is their high level of commitment.

Our product range includes frequency inverters, servo drives, drive motors, motors, clutches and brakes, connection technology and automation solutions, including controllers, industrial PCs, engineering software, visualisation, communication and I/O systems. Lenze is one of the first specialists in drive technology to integrate safety technology into its drives. Our services include consultation, engineering, commissioning, plant construction and customer service. This is supported by a world-wide service network which is available 24 hours a day under a single international telephone number (008000 244 6877

Frequency inverters are used for electronic speed control on machine drives. The needs of the market are wide and varied, and we can offer a homogeneous range of standard products for everything from simple speed control to complex applications with high requirements in respect of drive behaviour and functionality. Our drives are reliable in respect of operation, flexible in terms of application, easy to commission and meet high standards of quality. We can provide a solution to suit any requirement in the power range between 0.25 and 400kW.

Precise positioning – Positioning with frequency inverters

The frequency inverter series for process optimisation throughout all phases of the value-added chain.

The range of modular frequency inverters for standard applications with an extensive set of functions.

The flexible frequency inverter for complex applications with user-definable function block structure.

A sensorless vector drive with IP65 enclosure from 0.37 to 7.5kW needing no panel space and suiting wet or dusty environments.

The compact frequency inverter for simple applications with clear functionality.

Our most technically advanced inverter drive continues Lenze – AC Tech’s tradition of innovative compact inverter design. The performance and flexibility make the SMVector an attractive solution for a broad range of AC Motor applications and with several communications protocols available, networking drives and components into a system solution can be done now or in the future.

The SMVector NEMA 1 (IP31) is the most common and cost effective drive enclosure for a wide range of applications including packaging, material handling / conveying, positive displacement pumping, and HVAC systems.

The power ranges of the SMVector with NEMA 1 (IP31) include:

The SMVector Series can be used with 3-phase AC induction motors and is available in NEMA 1 (IP31) , NEMA 4X (IP65) ¹ and NEMA 4X (IP65) ¹ with an integral disconnect switch. Filtered input versions of the SMV are available in NEMA 4X (IP65) models for compliance with the CE EMC directive.

Programmable digital and analog I/O allow the drive to be configured for many application specific tasks such as multiple preset speeds, electronic braking and motor jogging to name a few. Like all Lenze – AC Tech sub-micro drives, the SMVector uses EPM memory technology for fast and efficient programming.

Technical documentation for the SMVector Series Drive, and all AC Tech brand drives, is available in our Technical Library.

¹ type 4X (IP65) enclosures are available for either indoor use, suitable for most indoor industrial environments; or indoor/outdoor use that offers UV protection and has higher impact strength at low temperatures.

The IP65 SMVector is designed to meet general purpose application requirements.

The IP65 enclosure means that the drive is designed to perform in the harshest of environments, even in areas with high levels of dust or moisture and in areas requiring washdown with low pressure jets. Choose the material of the housing (ABS plastic or Polycarbonate) which suits your application.

SMVector Drives are simple to use. They are easy to program with a integrated keypad – meaning that parameter setting and commissioning takes literally seconds! Impressive and flexible vector performance, a whole array of communication modules for industrial communication and last but not least an available Mains Disconnect option with Lock Off make IP 65 SMVector a very smart and cost effective Solution.

Naturally SMVector Drives are equipped with the unique EPM (Electronic Programmable Module). Parameter setting can be saved on the EPM and copied to other drives as often as required.

Drive features

The modular range of 8200 vector frequency inverters in the power range from 0.25 to 90 kW provides a complete and consistent solution with everything you need to facilitate operation, handling, diagnostics and communication. Pluggable function modules can be used to integrate the 8200 vector into the control and automation world of your machine or plant.

The compact dimensions save you space in the control cabinet. For customised cooling concepts, we can offer “push-through technique” and “cold-plate technique” versions. For operation, you can choose to use either the plug-in Keypad XT operating moduleor a PC running the user-friendly Global Drive Control easy operator software, which is available free of charge.

The devices for 400 V mains voltage are optionally available with the integrated “safe torque off” safe standstill) function from 3 kW upwards.

Precisely tailored to your application – this is what the new Lenze frequency inverter generation stands for. Our customers demanded Rightsizing which made us produce a frequency inverter series where each successive model as BaseLine, StateLine, and HighLine builds on the previous one in terms of functionality and drive behaviour. On each and every one, the installation, parameterisation, operation or service are identical. Combined with intelligent features, as provided by the memory module and the online-diagnostics the 8400 drives contribute to process optimisation and more added value in the engineering industry.

Modern systems are often designed in such a way that products can be replaced quickly and without complication. If a high degree of response and accuracy are also required, Lenze’s servo drive systems offer the necessary flexibility. Combined drive controller and servo motor packages featuring perfectly matched components provide solutions for a wide variety of requirements. Compared to mechanical and pneumatic solutions, servo technology is not only more responsive and accurate, but also better value for money and more wear resistant.

Our drive and automation technology is used in a wide variety of industries, for example in materials handling technology, in the packaging industry, the industrial handling sector, the robotics sector and in automotive construction. Our products are carefully co-ordinated and matched and can be combined as required to provide the right solution for your needs. Automation solutions with integrated software and system engineering and a global customer service network complete the offer. Our reliability combines with the quality of our products and services to enable us to increase the productivity of our customers in mechanical engineering and that of machine operators.

We have developed L-force in response to the increasing complexity of applications and processes. As well as being an innovative drive and automation product family, L-force is Lenze’s new and integrated solution portfolio.

9300 intelligent drives are ideally suited to the independent control of subprocesses within a machine. Taking existing standard applications as a starting point, individual drives can easily be extended with the help of function blocks that can be interconnected as desired; this takes the pressure off the central control and facilitates modular mechanical engineering. The series can be used universally in the power range 0.37 to 75 kW.

In order to meet the most diverse servo technology requirements, four software versions are available:

By using a uniform user interface, the need for training is reduced – once you have learned how to use it, this knowledge will never go to waste. 9000 servo drives can be integrated into current fieldbus systems easily using the pluggable AIF communication module.

The devices are optionally available with the integrated “safe torque off” (safe standstill) function.

A large number of system accessories finish off the entire product range.

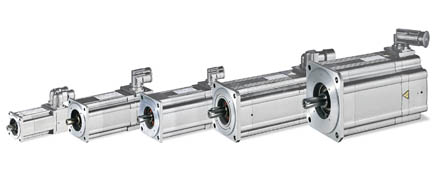

Low moment of inertia, excellent power-to-size ratio and high degree of operational reliability by design with a peak torques of up to 1100 Nm.

These highly responsive motors are characterised by their versatile and robust design, low moments of inertia, excellent power-to-size ratio and high degree of operational reliability.

The compact design and low moments of inertia of these motors make them suitable for use in high-response applications. Whether you opt for a naturally-ventilated or a forced-ventilated version, MCA asynchronous servo motors support a power range between 0.8 and 53.8 kW as well as rated torques of up to 280 Nm and peak torques of up to 1100 Nm. The electronic nameplate makes for easy connection of 9400 servo inverters and , cURus- and GOST-approval which comes as standard, promotes universal use.

Expand your horizons with the appropriate accessories.

Meeting stringent requirements in terms of response, precision and excellent power-to-size ratio.

The motor sizes have been carefully graded and offer rated torques from 0.8 to 64 Nm (0.25 to 10.0 kW) and peak torques of up to 191 Nm. As a result, finding the optimum motor for any drive task is easy.

Expand your horizons with the appropriate accessories.

We are driven by the demand for machines and systems that can deliver increased productivity, flexibility and safety.

When used in conjunction with highly dynamic synchronous or asynchronous motors, high-capacity geared motors can meet maximum requirements in terms of dynamics, positioning accuracy and durability. Lenze’s wide and varied range of geared motors combines the best in functionality with compliance with the many industrial standards.

If you are looking for a partner with the right expertise, Lenze, with its range of high-performance gearboxes and geared motors with scalable functions, is the perfect choice. Whether you are interested in individual components or complete drive systems, we will be happy to answer any queries you may have about project planning and commissioning and our after sales service staff are always there to help.

The excellent performance of these 3 and 4-stage integrated right-angle gearboxes sets them apart. Thanks to the robust cast iron housing, high permissible torques and closely stepped speed reduction ratios, they can meet even the most stringent of requirements.

The gearboxes/geared motors are used in the following areas:

Drive-end versions

Output-end versions

These 2 and 3-stage parallel-axis gearboxes are primarily used as shaft-mounted gearboxes. The gearbox has a space-saving design and is easy to mount. As well as enabling internal power or torque sharing, the output shaft is accessible for further use (e.g. for installing encoders).

The gearboxes/geared motors are used in the following areas:

Drive-end versions

Output-end versions

This 2-stage, right-angle gearbox for use in low to medium applications is characterised by its high efficiency, lightweight design (thanks to the aluminium housing) and wear-free gear teeth.

With Lenze bevel gearboxes/geared motors, you will benefit from lightweight designs and low life cycle costs – they are efficient, economical and fit for the future!

The gearboxes/geared motors are used in the following areas:

Drive-end versions

Output-end versions